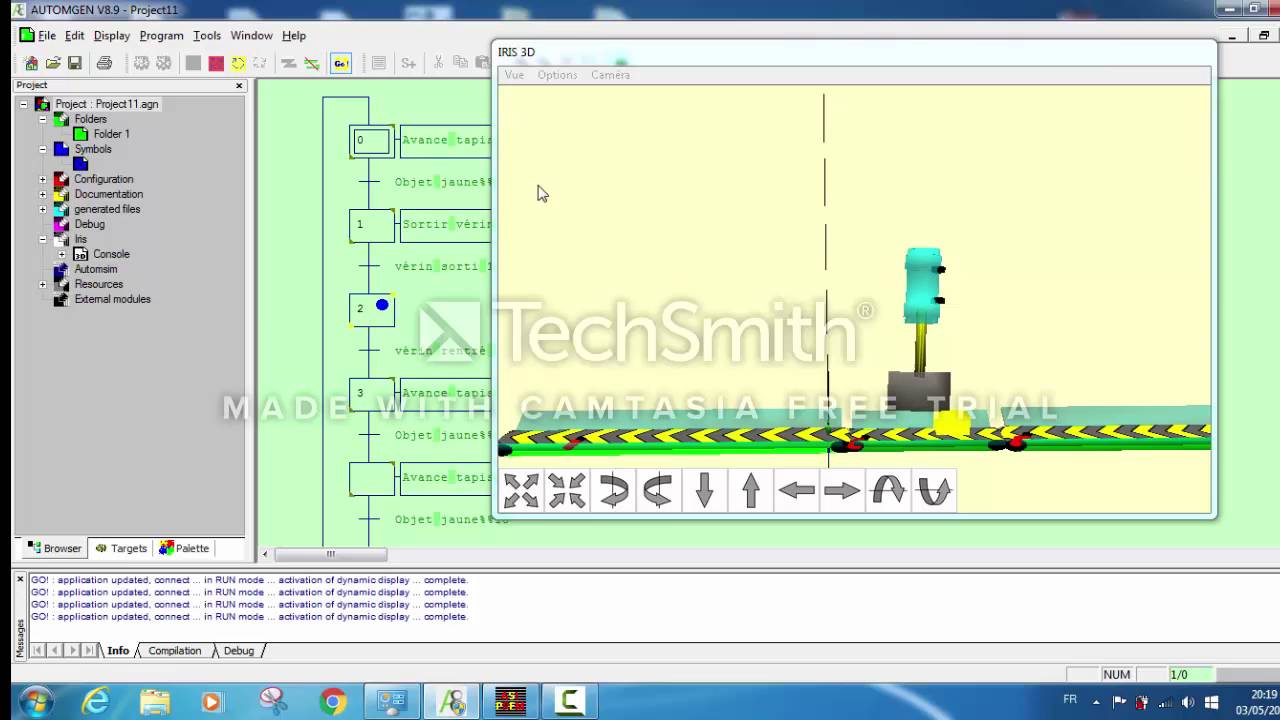

When Pumps are operating in Series, the effects of Pump failure is more serious than Pumps which are set to operate in Parallel. The actual Rated flowrate of Pump-A and Pump-B is where the System Resistance Curve crosses the Series Curve as shown below, not where it crosses the individual Pump Curves: The schematic below shows the Head & Flow curves plotted for Pump-A, and the Series Curve which is plotted by totaling the Heads of Pump-A and Pump-B at the same Flowrates. Then start Pump-B with its discharge throttle valve previously opened to approximately 30-40%, which should then be gradually opened, to ensure that Pump-A & Pump-B produce the Rated flowrate. The correct starting technique, once the Pump-A and Pump-B and the interconnected piping are primed full of the pumping liquid, is to first start Pump-A which is the booster pump feeding Pump-B. Mechanical seals and thrust bearings must also be reviewed on the B pump when operating in series. Even though Pump-B is identical to Pump-A in differential pressure and flow rate, the higher suction pressure it experiences means that care must be taken to select a pump that can meet the higher working pressure. So, it is important that Pump-B is rated for the higher Suction and Discharge Pressures.

The schematic of 2 identical pumps connected in Series is shown below:Īs you can see in the above schematic, the Pump-B Suction pressure is the Discharge pressure of Pump-A. So, each of these 2 Pumps in Series is lower cost, lower power, and potentially more reliable as a system than a single larger pump that produces the same heads as the total of the two smaller Series pumps.

The purpose of pumps operating in series is that, at the same flowrates, the Head (differential pressure) of both pumps is additive. The term Pumping in Series means that 1 pump acts as a booster to feed another pump. Predict-Plus – Remote Pump Monitoring System.ANSI/ASME B73.3 Sealless Horizontal Process Pump

0 kommentar(er)

0 kommentar(er)